How to adjust the color of external electronic files?

Time:2023-09-14

Views:666

External electronic documents are generally produced by advertising companies, which are basically produced according to the printing requirements of sheetward offset press, the sum of the order value is 320% ~ 340%, the dot increase value is 20%, the use of GCR color separation mode, select the medium black plate, such a color separation setting with sheetward offset printing problem is not big, but if the commercial rotary press printing, There will be color problems.

Treatment scheme selection

Since the color separation Settings of external electronic files are not suitable for commercial rotary printing, in order to solve this problem, we propose two solutions.

1. Re-color all the images in the original file

Re-color all the pictures of the original file, that is, convert the customer‘s adjusted pictures into RGB format, and then re-color according to the printing suitability requirements of the commercial rotary press.

But the customer came from the PDF file, printing companies can not adjust their own color, contact customers will bring trouble to customers, and must also contact the advertising company of the producer of electronic documents, and advertising companies are not particularly understanding of printing suitability, communication is not smooth. In addition, this journal is a weekly, the printing time is relatively tight, if you want to readjust, the time is not allowed, and the readjustment after the final version will also bring hidden dangers. Generally speaking, this method is not advisable.

2. Adjust the color by adjusting the CTP output curve

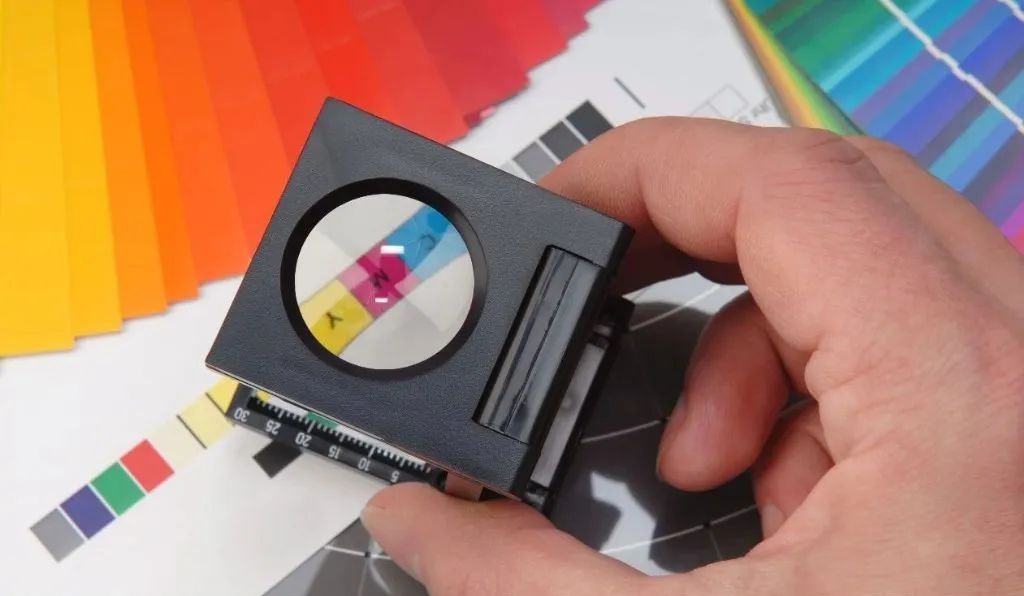

By analyzing the printing measurement and control strip on the printing proof of the last issue of the weekly, we get the following data: the intermediate adjustment dot increase value when printing with a commercial rotary press is about 25%, that is to say, after printing the dot at 50% of the printing plate, the dot percentage on the print is about 75%, and the dot increase is larger.

Open the client, select output management in the management tool, click on the curve management, pull out the CTP output curve when using a sheet offset press, found that the curve is basically a line with 45° horizontal coordinate, 51.7% of the points in the prepress file on the CTP version of the point percentage is 50.0%.

.jpg)

Therefore, if such a CTP version is directly printed on a commercial rotary press, the following problems may occur: the amount of ink is small, the middle color of the image is appropriate, and the density of the dark tone is not enough, the color saturation is not good, and the image contrast is small; If the amount of ink supply is increased, the saturation of the dark tone is appropriate, the light tone and the middle tone will be seriously increased by the dot, causing the color to be too dark, the picture is gray, there is no layer, and it can not catch up with the digital proof.

Based on the above analysis, we propose the following solution: the dot increase curve of the commercial rotary press is obtained through the printing measurement and control strip on the printing proof of the last issue of the weekly. According to the curve, the output parameters of the CTP are reset to compensate for the dot increase of the commercial rotary press.

Implementation steps

In order to leave the amount of dot increase for the rotary press, we adjusted the four-color printing curve by analyzing and estimating the printing measure and control strip on the printing proof of the last issue of the weekly. Select "All curves use the same data", and adjust the output value at the input value of 25% from 24.3% to 32.0%, from 51.4% to 60.0% at 50%, and from 76.6% to 82.0% at 75%. Since the CTP output curve is the inverse function of the printed curve, after such adjustment, The middle tone of the output CTP version is down by about 9%, the light tone is down by about 7%, and the dark tone is down by about 5%.

After adjustment, we carried out the first trial printing, the printing effect is good, both to ensure the saturation of the dark tone, but also to meet the level of the middle tone, but also to highlight the bright tone, the printing operator also reflects that the color is easier to follow, which shows that the adjustment direction is right.

Comparing the first trial printing proof with the digital proof, we found that the medium dark of the printing proof and the digital proof are very close, but the brightness tone is somewhat bluish (mainly reflected in the skin color of the characters), the reason may be that the paper color is a little bluish, so we use the complementary color principle to adjust the printing curve of the M plate, and set the output value at 20% of the input value of the curve. Adjusted from 26.0% to 23.0%, that is, the percentage of points of M version bright adjustment is 2% to 3% more than other color versions. According to the adjusted curve for the second trial printing, the printing effect of the brightening character skin color is obviously better, but the highlight of the M version feels a little lacking.

Therefore, we fine-tuned the printing curve for the third time, adjusted the printing curve of the M plate, and adjusted the output value of the curve at the input value of 5% from 8.0% to 7.0%, from 15.0% to 14.0% at 10%, and from 21.0% to 20.0% at 15%. That is, the percentage of outlets at 5%, 10% and 15% of the CTP version is 1% more than the original. According to the CTP output curve adjusted for the third time, the CTP plate was output and printed on the machine. The printing effect was very good, and the customer was very satisfied.

We have tracked and monitored the printing of this issue of weekly magazine. The printing effect is stable, the color saturation is high, the tone and level are restored well, and the customer is very satisfied.

In summary, if the external electronic documents received by the printing company are not suitable for the current printing conditions, it is advisable to take the method of adjusting the printing curve described in this article to try, and may get unexpected results.