How to effectively control costs in customized packaging?

Time:2024-05-10

Views:2611

Today we will focus on packaging costs and talk about how to control costs in customized packaging.

First of all, we need to understand what parts of packaging costs generally consist of?

The customization process in the industry generally generates design fees, pre-press fees, material fees, printing fees, post-press processing fees, etc. However, it should be noted that there is also a difference between fixed costs and non-fixed costs.

For relatively fixed cost components, we can start with material replacement or process simplification.

On the premise of ensuring product safety, try to replace high-cost consumables with more cost-effective paper to reduce cost investment.

Or on the premise of ensuring packaging quality, simplifying the post-processing process as much as possible can reduce the cost of packaging boxes to a certain extent.

1.Material fee

For packaging or printed matter, material costs account for a large proportion of the entire cost. Not only basic consumables, but also printing fees, printing material fees, anodized aluminum fees, etc.

2.Printing fee

The floating range for such fees will be relatively large. For different types and grades of printing equipment, different printing plants or printing processes, the printing fee standards are different. Color printing is generally priced by color order. When the overall print volume is relatively small, the starting price will be calculated.

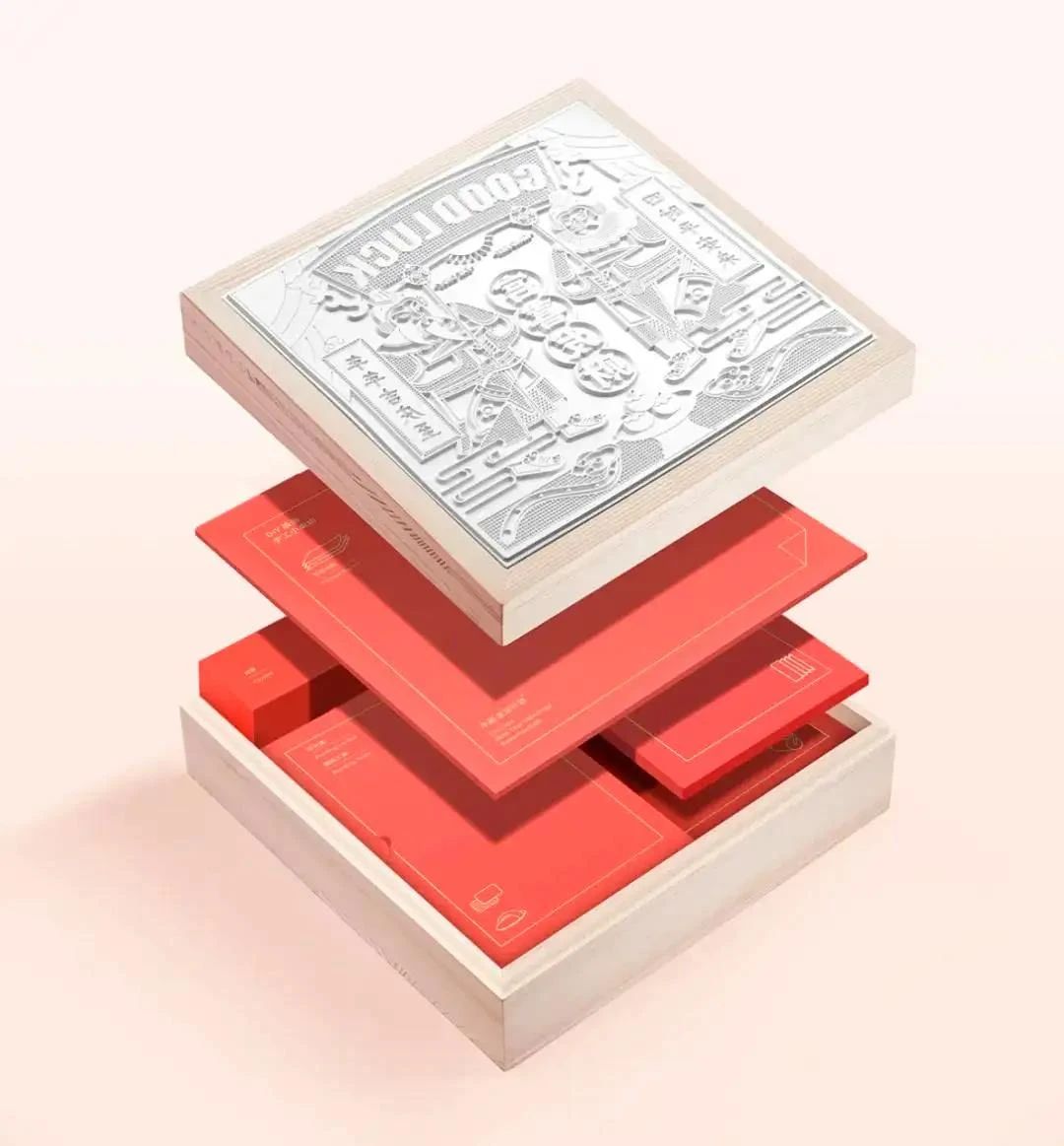

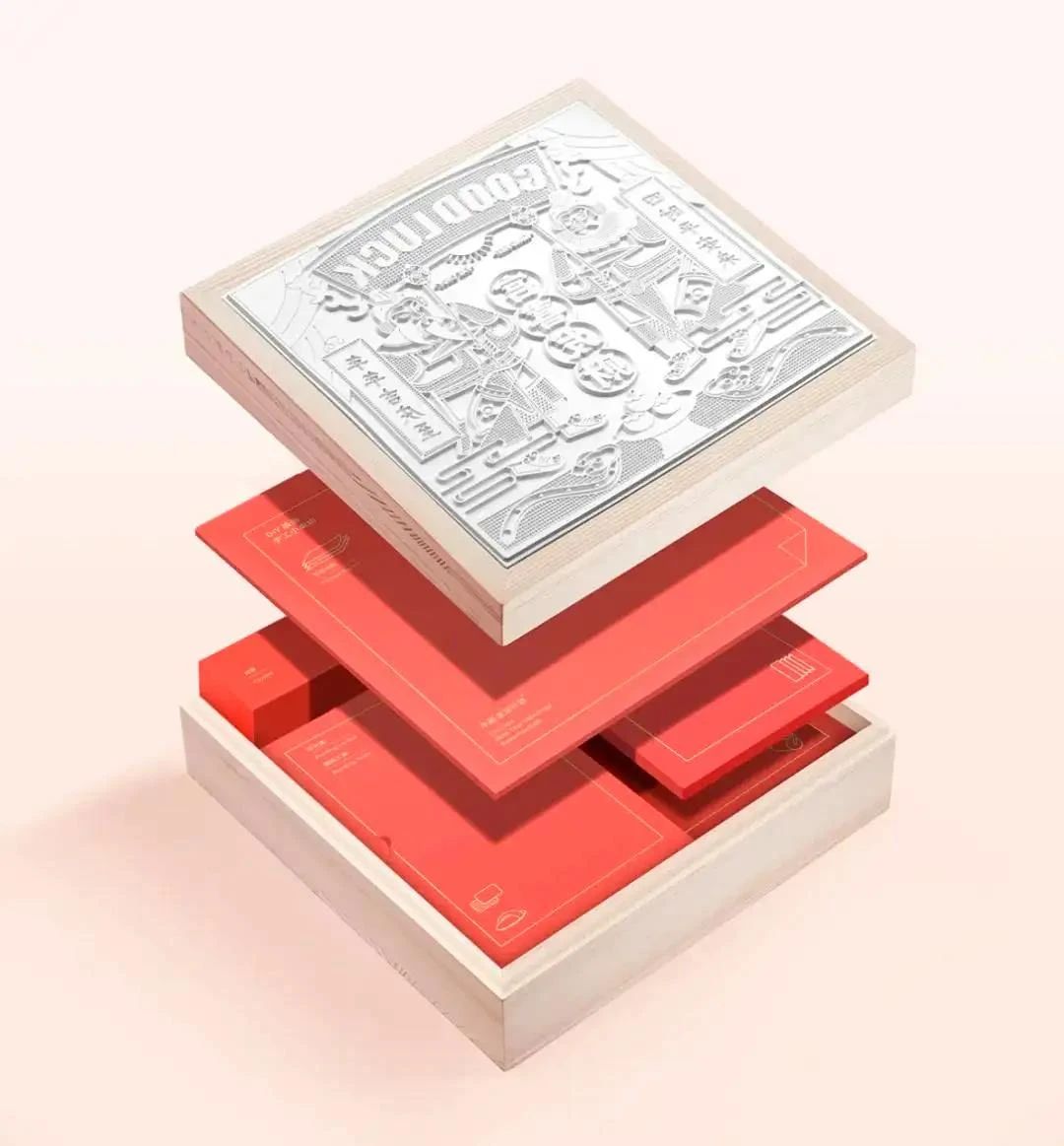

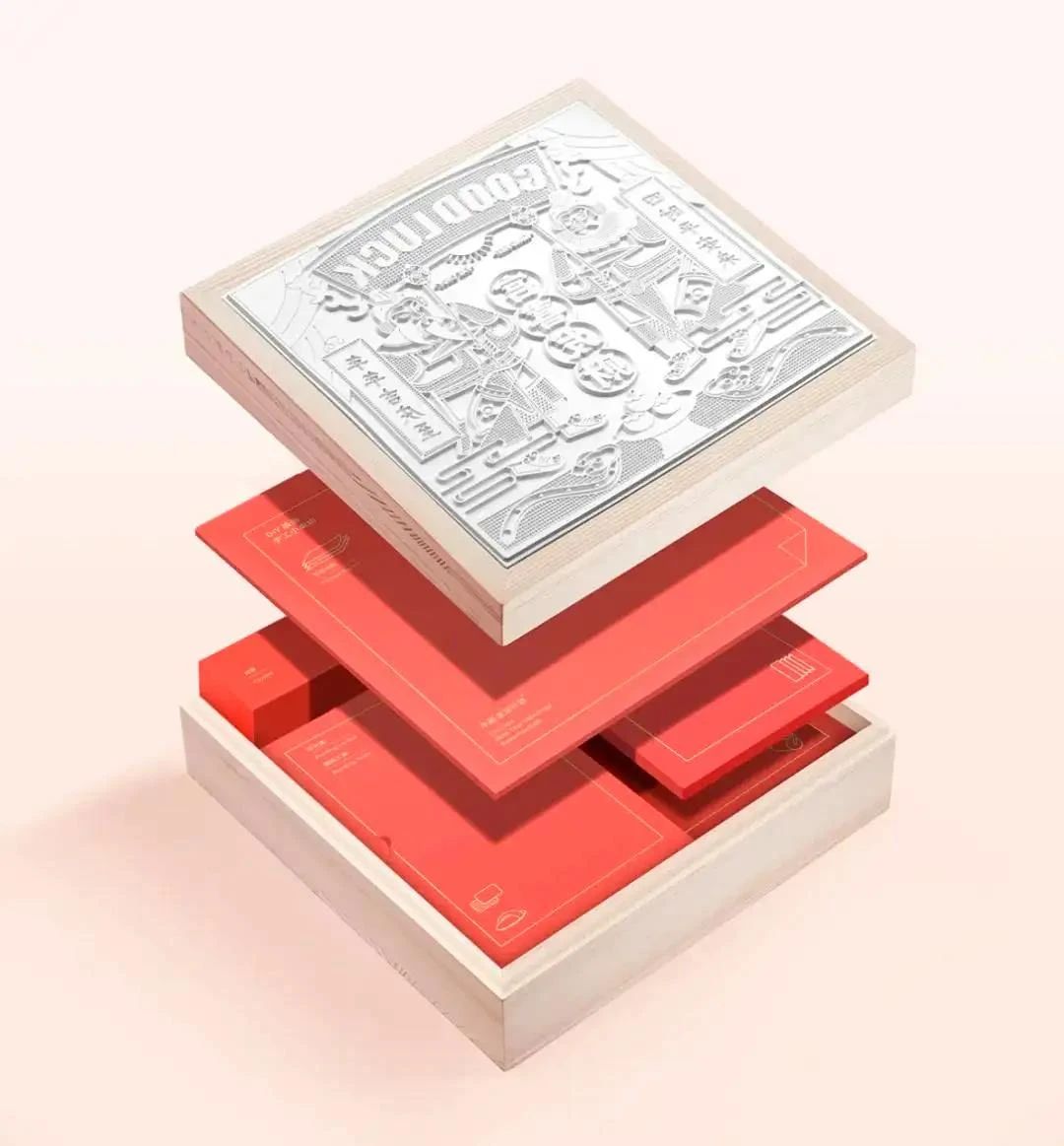

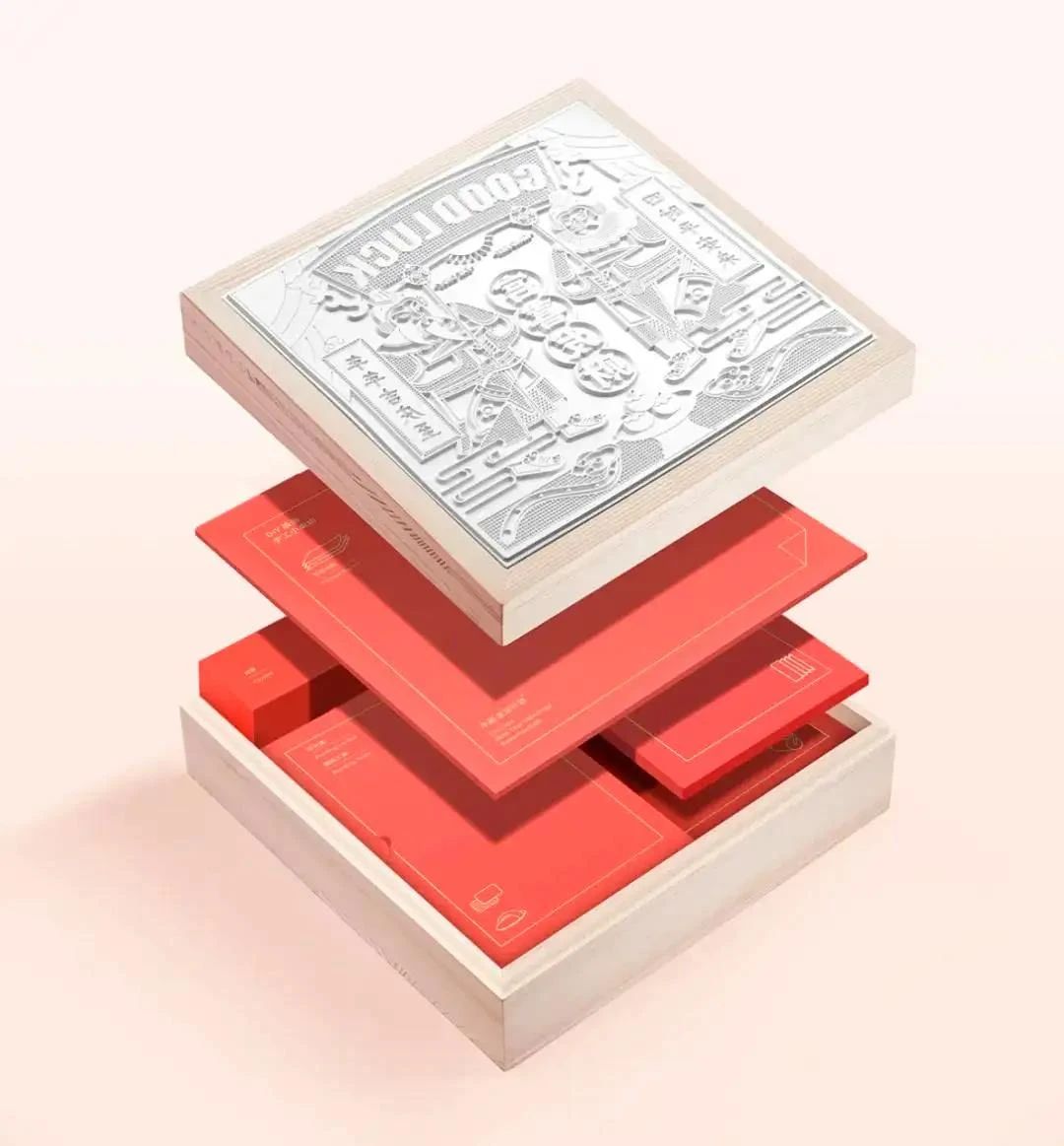

3. Post-press processing fee

For packaging, design and production are only the preliminary process. If you want to make the product more textured, post-printing process is indispensable. The calculation method of this type of processing technology is mainly based on the number of processed pieces or area. For example, processes such as glazing, lamination, and hot stamping are generally calculated based on the processing area.

In this part of the cost, the proofing fee accounts for a relatively large proportion. If the design draft is frequently modified and multiple proofings result, the resulting proofing fee can even reach more than 10,000 yuan.

Therefore, maintaining smooth communication channels between enterprises, design companies, printers, and factories and reducing the number of reworks and proofings is crucial to saving this cost. At the same time, it can also save invisible costs such as labor and time.

1. Design fee

If you choose a third-party design company, design fees will be involved. There are single-piece calculation method and multi-piece calculation method for calculating design time. The single-piece calculation method is generally used for packaging cartons.

However, if the design layout is adjusted too many times, it is not ruled out that this part of the cost will increase. Of course, it is generally determined by both parties through negotiation, and the flexibility is greater.

2. Pre-press fee

Pre-press costs include image scanning, imposition, film production, proofing, etc. Scanning is priced based on image information size (megabytes), imposition is charged based on format size, and proofing is charged based on format and number of colors.

Especially for proofing, a proofing fee will be incurred for each proofing.

In addition, these are all visible costs. In actual packaging customization, special attention needs to be paid to some invisible costs.

For example, labor costs. If a company chooses to design its own packaging, the labor costs of designers must also be calculated. The longer the design takes, the higher the cost. In addition, there is a time cost. If problems occur in design, production, etc. and frequent rework occurs, delaying the time to market of the product, the losses caused are sometimes immeasurable. Therefore, if you want to avoid high costs, you need to adopt different coping methods for the above different types of expenses.