Tips to improve ink stability

Time:2024-08-11

Views:1819

4. Before printing, do a good job of early adjustment according to experience.

First, the amount of ink in each color group is roughly adjusted according to the graphic area of the proof or plate. The job is easier to do on machines equipped with ink remote control systems. Do not adjust the amount of ink in a wide range when printing, so as not to cause a large color difference.

Secondly, according to the requirements of the production process sheet and the characteristics of the product, various links such as Feida, paper feed, ink performance, and pressure are adjusted in advance to avoid confusion during formal printing. Among them, ensuring Feida‘s reliable, continuous and stable paper feeding is the most important. Experienced operators pre-adjust blowing, suction, press foot, press spring, press wheel, side gauge, front gauge, etc. According to the width and thickness of the paper to adjust the paper, and straighten out the movement and coordination between the components, to ensure the smooth feed of Feida paper, to avoid Feida beat caused by different ink shades. It is recommended that experienced workers pre-adjust Feida.

In addition, according to the paper quality and graphic area of the printed matter, the viscosity, fluidity and dryness of the ink should be properly adjusted in advance to improve its printability and ensure normal printing, and the ink color should not be different due to frequent shutdown to clean the paper wool and ink skin on the rubber blanket and printing plate. If a variety of glue remover and ink oil are added in the middle of printing, color difference will be generated.

In short, do the pre-adjustment work before the boot, the fault after the formal printing can be greatly reduced, and you will have time and energy to focus on the ink.

2. Correctly adjust the pressure of water and ink roller.

In the printing process, the graphic part of the plate must provide continuous, uniform, and appropriate amount of ink to obtain a consistent ink color print. Therefore, the proper contact and rolling relationship between the ink roller and the plate must be maintained to achieve good ink transfer. If this work is not done carefully and incorrectly, the ink color will not be consistent. Therefore, each time the water roller and ink roller are installed, the ink roller method is used to adjust the pressure between them one by one, rather than the traditional stopper tension method, because the latter due to various human factors, the actual error is larger, so it is forbidden to use in multi-color high-speed machines. As for the width of the roller, it is generally appropriate to 4 to 5 mm. First, adjust the pressure between the inking roller and the inking roller, then adjust the pressure between the inking roller, the inking roller and the plate roller, and finally, adjust the pressure between the inking roller, the water roller, the water roller and the intermediate roller, and the pressure between the water roller and the plate roller. The ink stick between these channels should be 6mm.

The equipment should be re-adjusted after two or three months, because the diameter of the ink roller will become smaller after a period of high-speed friction, especially in the transmission. When the pressure between the rollers is low, the ink that accumulates on the rollers cannot be transferred downward. When printing is resumed after flight or stop, the ink color of the first dozens or even hundreds of sheets is darker because of the large amount of ink, and it is difficult to achieve the ideal ink balance. This fault is generally not easy to find, and is only obvious when printing fine prints. In short, the operation in this area should be meticulous and scientific, otherwise it will cause different shades of ink at the mouth and end of the water, ink strips, and printed products, which will artificially cause faults and increase the difficulty of operation.

3. To achieve ink and wash balance.

As we all know, ink balance is an important content in offset printing. If the water is large and the ink is oil-in-water emulsified, of course, the print quality will not be ideal.

First of all, ensure that the pressure relationship between the water and the ink roller is properly adjusted, and the content of the lubricant and isopropyl alcohol meets the general standard. On this basis, start the machine, turn off the water supply and ink roller, and then stop to check the plate. The printing plate is slightly sticky 3mm. Taking the water amount at this time as the initial printing water amount can ensure the normal printing of general graphic products and basically achieve the balance of ink and wash.

Secondly, the water consumption is flexibly adjusted according to other factors, such as large plate graphic area, rough paper surface, ink need to add additives, and printing speed, air temperature and humidity.

In addition, when the machine begins to print, the body temperature is low, but when the machine runs for an hour or two at high speed, the body temperature, especially the roller temperature, will more than double, or even higher, and the water consumption will gradually increase until the ink reaches a new equilibrium state.

It can be seen that it is not easy to achieve the balance of ink and wash, and the operator needs to be careful. Otherwise, the color stability of the ink is difficult to control, and it is impossible to print high-quality prints.

4. Calibration and color sequence of proofs.

In the production, we often encounter such situations: the samples provided by the customer are not standard, or only a color spray draft is provided, and there is no proof. At this time, it is necessary to analyze the specific situation, and it is not necessary to increase the amount of ink or reduce the amount of ink to chase the effect of the sample. Even if it is initially close to the proof, the stability of the ink color cannot be guaranteed, and thus the final quality of the print cannot be guaranteed. In this regard, the printing house should be in a serious and responsible attitude, actively exchange views with customers, point out the problems in the sample and put forward suggestions for modification, and then make appropriate adjustments and reprints after consent.

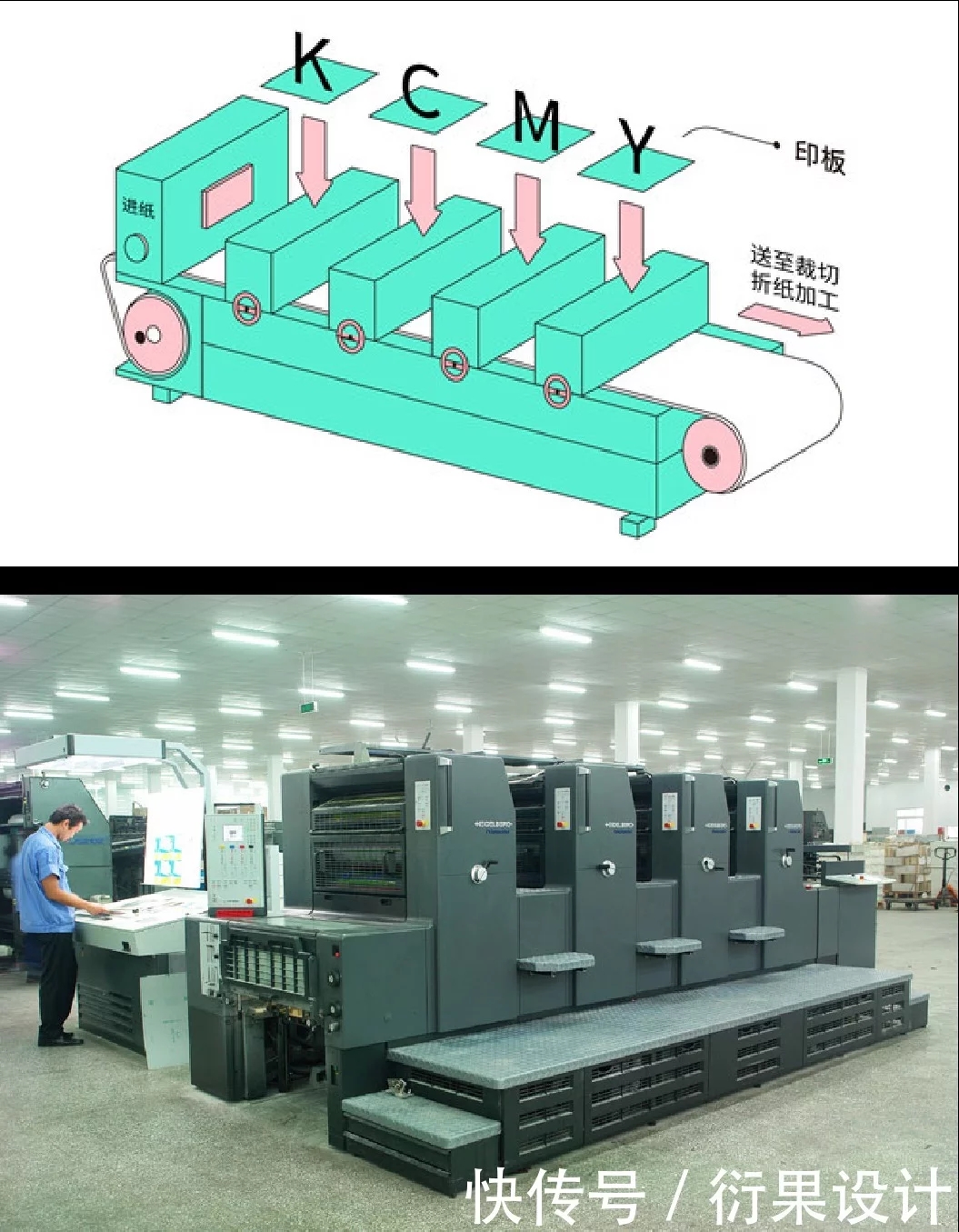

In production, the printing color sequence of the multi-color machine is usually determined by the viscosity of the ink. Because in multi-color printing, the ink is overprinted by wet pressing together, only by obtaining the best overprint rate can you print a stable and consistent ink color print. The arrangement of the printing color sequence must conform to the characteristics and quality requirements of the printed matter, and cannot be unchanged. At the same time, the viscosity of the ink can be adjusted. For example, if a cover is mainly purple, and a cover is mainly sky blue, then its printing color order is different. The former first green after magenta, the latter first magenta after cyan. Otherwise, the color of the overprint will be spotty, uneven and unstable. If the print is mainly black, the black is arranged in the last color group as far as possible, so that the gloss of the print is better, and the scratch and color mixing inside the machine are avoided.

5. Cultivate good operating habits and strengthen the sense of responsibility.

Any work must have a high sense of responsibility and a strong sense of quality. We must standardize the process operation and adhere to the good traditional habits of "three levels" and "three presences". Take proofreading as an example: when comparing the signature sample on the sample, the difference in distance, Angle, light source, etc., will cause visual deviation, resulting in inconsistent ink color. At this point, the signature sample must be removed from the sample and carefully compared. In addition: the long-life printing plate needs to be baked to reduce the ink color difference caused by changing the plate; The blanket should be cleaned frequently, and more blotting paper should be placed after each cleaning to stabilize the ink color; The five or six new prints after Ferton are too dark to draw, and the printing speed should not be greedy; It is important to keep the machine stable and normal; When adding ink, because the new ink is hard and the fluidity is poor, it is necessary to stir several times to avoid affecting the amount of ink and causing poor ink color.

Operators should continue to study, carefully observe and analyze, find out the factors affecting ink color changes from all aspects, and take appropriate measures to prevent and overcome, and strive to improve the stability and consistency of print ink color, and effectively improve the quality of print.